Computational tools

Related Videos

The Preventive Maintenance

Figures of Preventive maintenance Training of Theory in Bim Son Cement Plant and surveying practice in Hoang Thach Cement Plant

Preventive maintenance is execution of cost-effective maintenance tasks at predetermined intervals

- to check the current physical condition

- to reduce probability and/or impact of a failure in operation

- to maintain a desired level of performance of an equipment

PURPOSE OF PREVENTIVE MAINTENANCE:

Maintain the operating conditions according to the criteria of the equipment with the lowest cost

Optimize the readiness of the device

OBJECTIVES OF PREVENTIVE MAINTENANCE:

Optimal use of equipment with minimal maintenance costs

Reduce losses from damage effectively by regular inspections, equipment diagnostics and periodic maintenance.

Maintain the machine at the desired performance

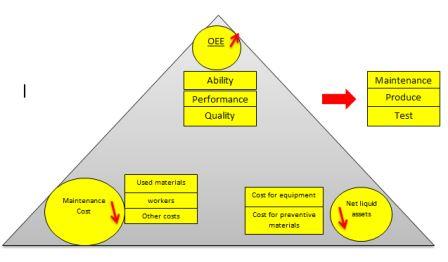

Figure 1: Objectives of Preventive Maintennance

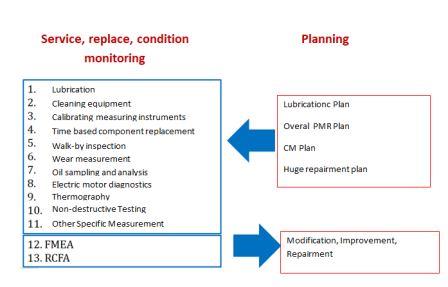

SCOPE OF WORK OF PREVENTIVE MAINTENNANCE:

Preventive maintenance level 1:

It gives an overview on the Basic Preventive Maintenance Philosophy and structure, application and practice such as:

- Walk – by Inspections

- Preventive Maintenance Routines

- Lubrication

The purpose is to lay down and implement the basic philosophy of preventive maintenance and develop the habit of sustaining this maintenance practices.

Preventive maintenance level 2:

This is more of an in depth and advanced application of the Preventive Maintenance Philosophy and refers to the different technical methods and tests, such as:

- Vibration Measurement and Analysis

- Oil Analysis

- Application and Practice of Non Destructive Testing (NDT)

- Electric Motor Diagnostics (EMD)

The purpose is determining the condition of the equipment and its main components. By detecting anomalies at an earlier stage, more time will be left to plan an adequate corrective measure. More training and skills are required in order to succeed with this MAC element, although some of the techniques will be outsourced to specialized companies.

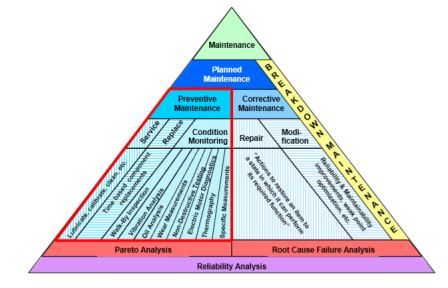

Figure 2: Scope of work of preventive maintennance

Preventive Maintenance Organization:

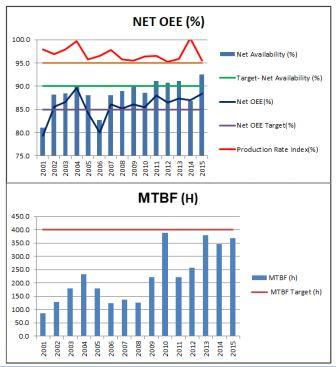

Example of achieved results of a plant applying the preventive maintenance:

Maintaining the growth of availability althougth Kiln Capacity has been increasing through years. It proves that the preventive maitenance has the great contribution to equipment availability

Figure 3: Capacity of Kiln through years

Figure 4: Achieved Results

Represent customers:

The preventive maintenance including therory and pratice has been carried out for customers: the total training for subsidiary company of Vicem company, Hoang Thach Cement Plant, Bim son Cement Plant ( Preventive maintenance level 1)

a

Articles

- KILN UPSET CONDITIONS AND SUPPORT SERVICES (31.10.2020)

- PROVIDING THE KILN OUTLET SEALS (30.10.2020)

- PROVIDING THE KILN INLET SEALS (30.10.2020)

- PROVIDING AIR BLOWER FOR INDUSTRIES (07.02.2020)

- SUPPLY FABRIC FILTERS FOR INDUSTRIES (14.11.2019)

- PROVIDING AIR BLASTER FOR INDUSTRIES (11.11.2019)