Computational tools

Related Videos

PROVIDING THE KILN INLET SEALS

PROVIDING THE KILN INLET SEALS

Introduction

DAL Makina Tasarım is a part of Dal Engineering Group (DEG), who is providing turnkey projects with his group companies and giving engineering services to different industrial sectors in all around the world. DEG provides solutions, including procurement of the equipment & machinery, engineering, erection, automation and all electrical works, raw materials, for cement, mineral, energy, environment and recycling industries. Cost Solutions Company represents DAL to supply sealers in Viet Nam. With the most advanced and modern techniques, we ensures that bringing the sastisfied to customers.

TECHNICAL DESCRIPTIONS

1. DESIGN OBJECTIVES

The goal was to manufacture a seal implementing simple mechanical solutions to meet the following objectives:

- Provide effective leak tightness around the kiln discharge hood to prevent cold air ingress or release of hot gases and particles;

- Improve pressure stability in the kiln;

- Allow installation on existing kilns without modifying the kiln shell or kiln inlet box.

2. DESIGN FEATURES

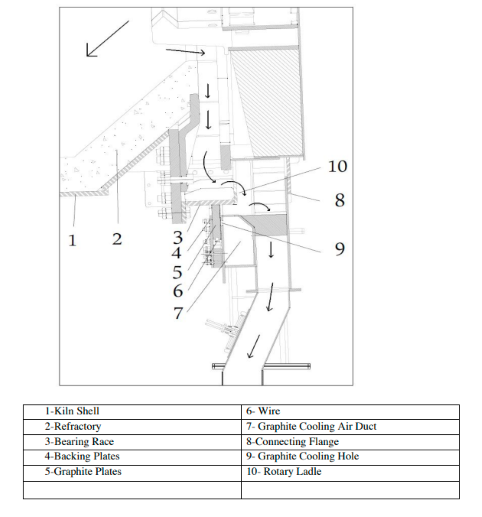

2.1 Leak tightness

Graphite plates are installed to form a static barrier between the fume box and a circular bearing race rotating with the kiln.

Friction wear of the graphite plates on the bearing race diminishes after the start-up period. The service life of the graphite plates is 2 years or longer on

2.2 Temperature adjustment

Temperature regulation is provided inside the casing to extend the service life of the graphite plates by maintaining the temperature below the graphite oxidation threshold by the means of a lowpressure fan (60 mm w. g. maximum).

The air flow is regulated by manually adjusting valves on the connecting line between the seal casing and the fan. One valve adjusts the airflow to the top section of the casing, another to the lower section.

3. DESCRIPTION

3.1 Circular track

A circular track; (20 mm thick) is installed so that it is absolutely concentric with the kiln centerline. The track is mounted on the kiln shell on the existing kiln inlet cone

3.2 Casing

The self-supporting fixed casing, generally delivered in three subassemblies, rests on two legs, and is attached to the fume box:

- An inlet flange bolted or welded to the fume box (the assembly method is determined at the design stage depending on the type and layout of the fume box) ;

- A graphite plate guiding flange

- A graphite plate retaining ring;

- A casing with access panels, a regulating air inlet, a dust recovery hopper, and a double flap valve for dust removal without cold air ingress.

- 2 metal backing parts to complete the rear section of the casing to be welded on to the fume box

3.3 Graphite Plates

The seal comprises between 70 and 90 graphite plates 40 mm thick according to the kiln diameter.

The graphite plates are arranged symmetrically and are interlocking to enhance their leak tightness.

At the top of each plate, a grooved metal insert supports the cables to prevent friction wear. Guiding stops welded to the casing inlet flange prevent the plates from rotating.

The plates are held in contact with the track by metal cables and counterweights.

The upper cable restrains about 40 % of the plates, while the lower cable secures the others. The casing includes a threaded support rod for installation of each lower plate to ensure safety in the event of a cable failure.

The counterweight tension is adjusted at the installation. Ten percent extra plates are provided in case of damage.

3.4 Graphite Cooling

The graphite plates are cooled by a continuously operating low capacity blower (e.g. 8 000 m³/h with a static pressure of 80 mm w.g. for a 4.4 diameter kiln).

The airflow to the upper and lower casing is adjusted manually (during installation) according to the casing temperature.

The standard air duct from the blower to the air inlet (generally located at the top of the casing) is about 5 meters long

4. ASSEMBLY AND ERECTION

Articles

- KILN UPSET CONDITIONS AND SUPPORT SERVICES (31.10.2020)

- PROVIDING THE KILN OUTLET SEALS (30.10.2020)

- PROVIDING AIR BLOWER FOR INDUSTRIES (07.02.2020)

- SUPPLY FABRIC FILTERS FOR INDUSTRIES (14.11.2019)

- PROVIDING AIR BLASTER FOR INDUSTRIES (11.11.2019)

- (09.11.2019)